Adhesives

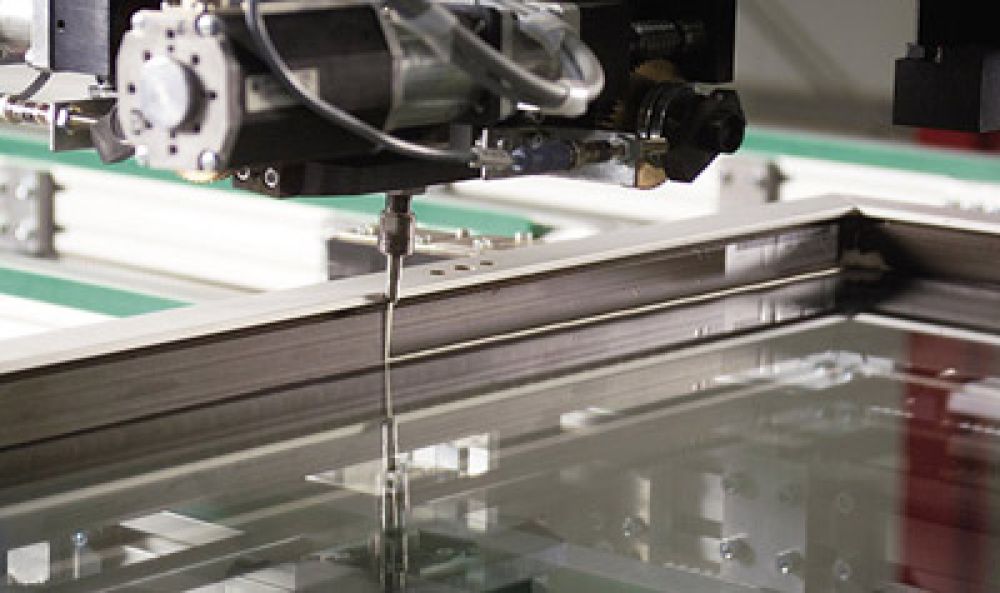

Liquid adhesives

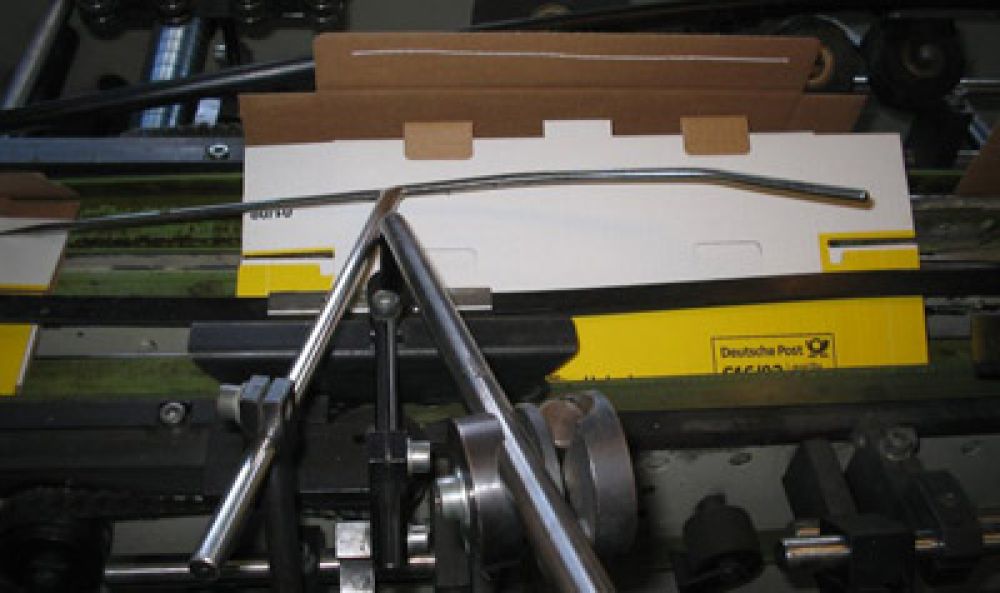

Binding of materials is a technique which is existing for centuries. In the beginning only solvable vegetable and animal glues (starch, dextrine, caseine, bone glue) were used for the gluing of relatively simple materials. During the time synthetics and plastics were introduced in the industry, they were also being used to formulate adhesives; the so called synthetic adhesives (like polyvinylacetates, synthetic rubbers, epoxy resins, dispersions and EVA). In the sixties hotmelts were entering the markets. This product contains 100% high solid -that means- without any water or solvent. By heating up, the mass becomes fluid and the adhesion will be created by cooling down, solidification. A good adhesion of substrates is most important during industrial applications. As a matter of fact, the finished product stands by a correct binding. In this context, pressing the materials together is of great importance, this means how better the contact, the faster the bonding is created and the shorter the pressing time will be.

Tanks with additives

Reactor polymerisation

Production unit

Common Terms

-

Adhesion

-

Is the binding of the dry glue film on the to be glued materials.

-

Cohesion

-

is the internal strength of the dry glue film itself.

-

Moisturizing

-

To reach an optimal adhesion it is neccesairy that the wet glue film will spread equally on glued surface.

-

Tack

-

Adhesion strength of the dry glue film.

-

Wet tack

-

Adhesion strength of the wet glue film.

-

Curing time

-

This is the complete processing time, which is needed to get a perfect bonding of the adhesive.

PVAc dispersion adhesives | INTADCOLD ® |

Casein glue | INTADCAS ® |

Dextrin glue | INTADDEX ® |

Latex glue | INTADLAT ® |

Kits and sealants | INTADKIT ® |

Spray adhesives | INTADSPRAY ® |

Starch glue | INTADPLAN ® |

Special adhesives | INTADSPEC ® |

Polysaccharide glue | INTADSAC ® |

Powder glue | INTADPUL ® |